In over 60 years TACOM has acquired considerable know-how and experience on various types of packaging filling lines all over the world. This puts us in the position to recommend the best system to solve your technical problems. We can provide specialised solutions to optimise production times and make other improvements to your packaging filling line.

These solutions include suction cups, carton feeders, glue, synchronisation, solving problems involving box insertion in the line, and more. Don’t hesitate to contact us for more information.

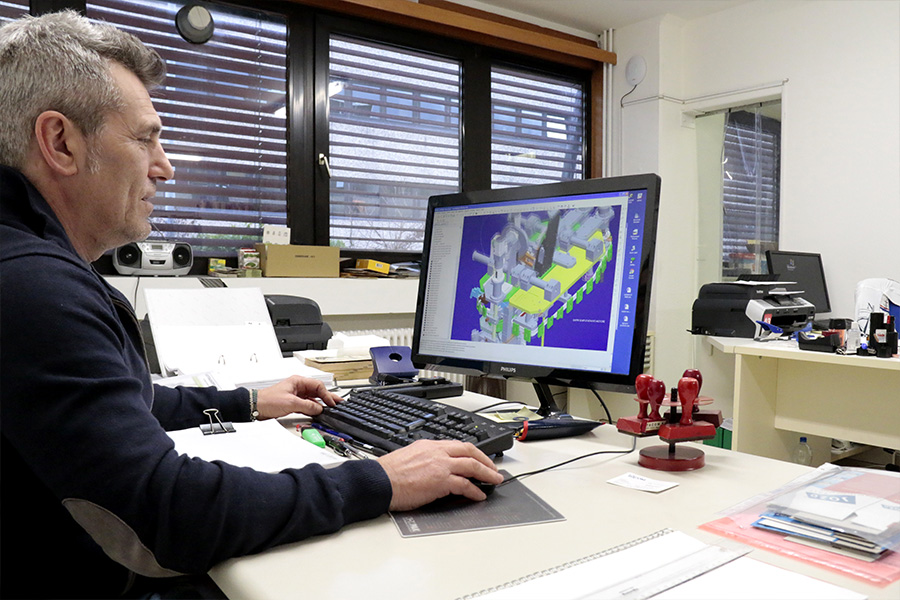

The TACOM team of specialised technicians and engineers provides customers with expert design solutions. We’ve been working with major manufacturers, product managers, packaging designers, co-packers and packaging filling line manufacturers for years.

Our goal is to find the best tailor-made solutions to meet the specific customer’s requirements, whether they be technical, production management or marketing requirements.

It’s only by listening carefully to these requirements that we can fully understand what the customer needs. This is how we came up with innovative dosing solutions, efficient ad hoc accessories for packaging filling lines, and solutions for optimising production. These solutions include Pour&Dose, Bispenser, Carton feeder, ERC, and more.

Technical modifications on packaging filling lines can involve notable labour costs and loss of production. Unexpected problems can arise, and they are almost impossible to predict for someone who doesn’t work in the sector. It’s vital to be able to count on competent experts you can trust.

TACOM offers its customers time-tested customer service to meet a wide range of needs, offering solutions to solve problems in the best possible way, as quickly as possible. Our team of technicians and engineers puts years of experience and know-how at your disposal to provide the very best assistance.

MaintenanceEffective, routine maintenance of your machines to change parts that can wear out, and keep them running smoothly is the best way to avoid costly corrective maintenance to repair faults.

TACOM offers its customers a routine maintenance plan, so machines continue to provide the expected performance, and even better performance if possible.

To do this, maintenance technicians must have an essential skill-set that’s constantly updated in refresher courses as part of their professional development, in order to coordinate the work required to guarantee fault-free, continuous production.

TACOM refurbishes 2nd-hand packaging machines in good condition, to offer performance that’s as good as new. 2nd-hand machines that have been carefully checked, refurbished and updated, can often guarantee the same quality standards and reliability as a new machine. These updated machines can be cheaper than a new one, and an inserting machine for TACOM dosing systems can also be included. Get in touch to find out more about our latest 2nd-hand packaging machinery special offers.